Commitment to Safety Safety by Design

When it comes to safety, positive results are what really matter most. Diamond has earned a safety record, backed by real world data, that is second to none. Our primary design goal is to build aircraft that are a pleasure to fly, yet forgiving and safe, while offering maximum protection in case of an accident. To accomplish this, we invest in two key safety strategies, Active and Passive Safety.

The best accident protection is to avoid them in the first place. Active Safety features and characteristics help do just that.

Active Safety refers to all the features and characteristics of an aircraft that help pilots avoid an accident. These include:

- unparalleled visibility

- agile yet forgiving flight characteristics

- continued controllability through a stall

- positive stability

- superb runway and climb performance

- high crosswind capability

- system and structural redundancy

- comfortable pilot workload

- reliable power

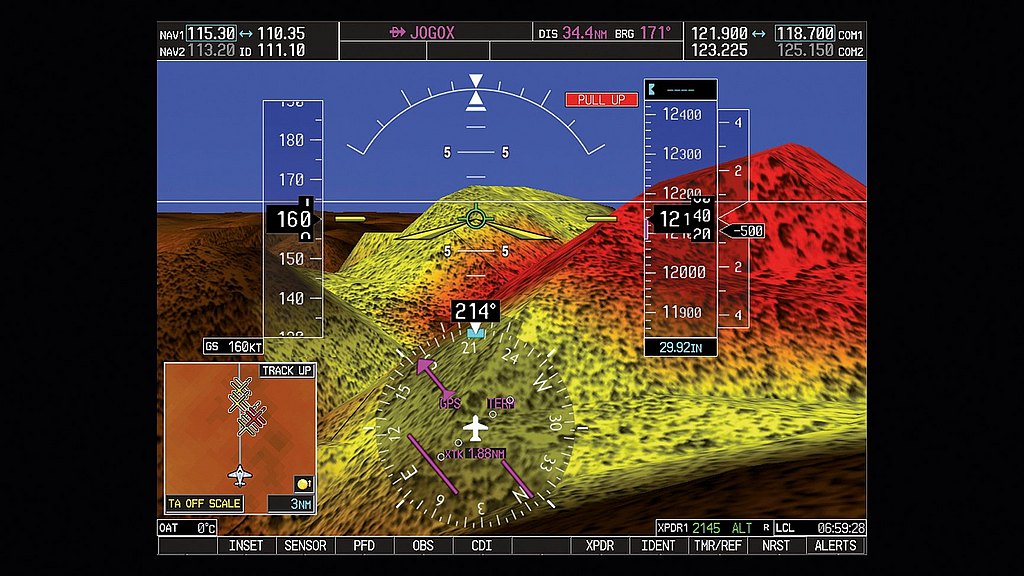

- the latest in avionics technology (integrated glass cockpit and digital autopilot)

Beyond that, active safety includes the matching of an aircraft design to its intended mission and pilot capability.

Our single engine piston models are especially docile and well suited for expert and novice pilot alike.

Our high-performance aircraft offer ice protection and twin engine safety, yet are easy to fly with simple single lever power controls.

Passive Safety

Unfortunately, not all accidents can be avoided. Passive Safety features are the second line of defense and help minimize the probability and degree of injuries.

Passive safety elements include:

- structural integrity of the cabin under crashloads

- effective occupant restraint

- impact energy absorption

- unobstructed headstrike zones

- flammable fluid fire protection

Diamond Aircraft's Safety Cell

Each Diamond aircraft incorporates an integral cabin surrounding composite “roll cage” structure, which is stiff and strong to provide survival space and protection in case of impact. With the adoption of crashworthy composite cockpits, Formula 1 race car safety evolved from fatal injuries and fires being commonplace to fatalities and fires becoming virtually unknown. Similarly, a Diamond aircraft’s non-critical structure is allowed to fail to help absorb crash energy while the cabin structure is designed to resist crushing and penetration to afford maximum occupant protection.

Occupant Protection

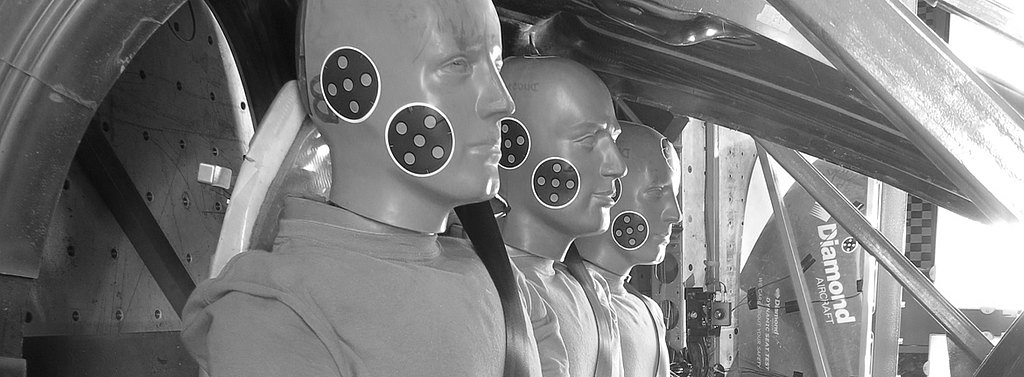

Integrated fixed seat shells with energy absorbing crash elements, antisubmarine geometry and three-point shoulder and lap restraints offer effective, yet comfortable occupant restraint which is critical to crashworthiness. Diamond performs dynamic crash tests not only of seats, as is typical, but of the entire fuselage cabin structure to test structure, seats, and restraints as one system. Details, such as breakaway glareshields, maintaining distances between heads and rigid structures, further enhance the survivability.

Flammable Fluid Fire Protection

Survivable accidents should be exactly that – survived. Diamond takes special measures to minimize the probability of post-crash fires.

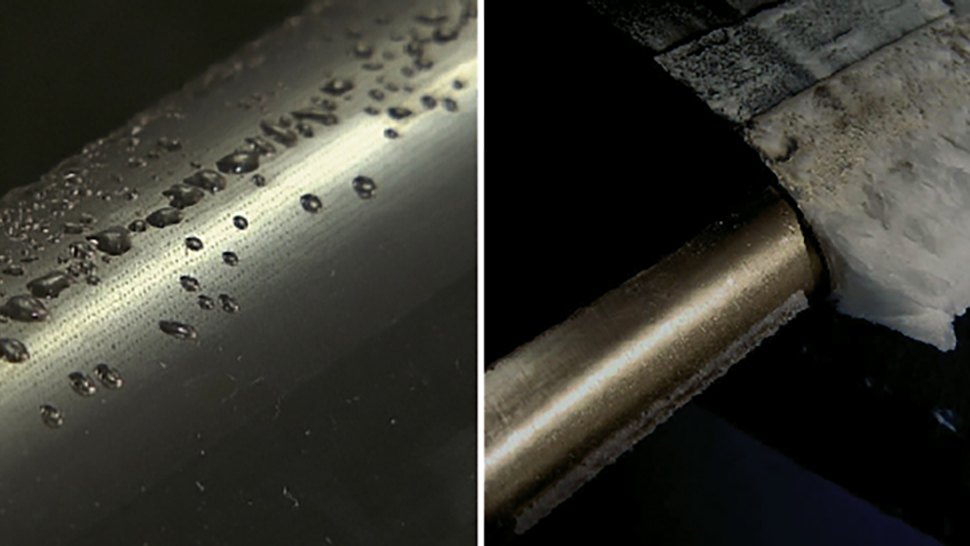

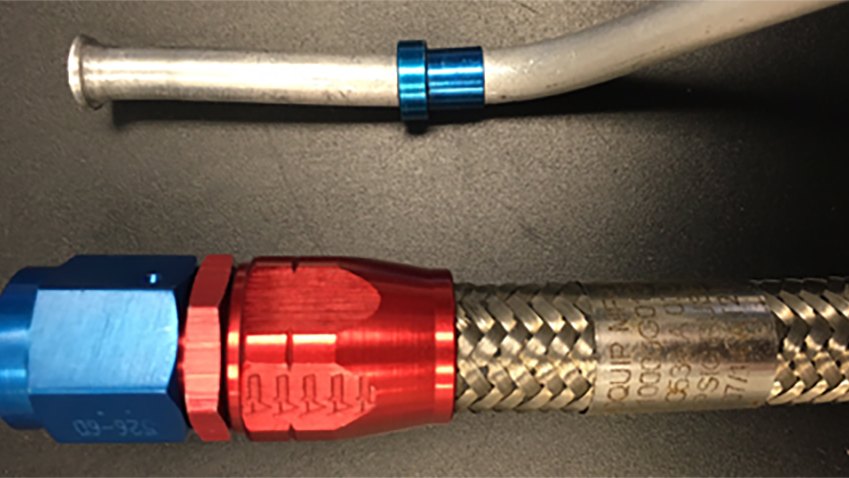

Fuel Lines

Typical in aviation are light, but fragile, rigid thin-walled aluminum fuel lines. While these tubes are used in many other aircraft, they unfortunately rupture easily in a crash when supporting structures are deformed. To help prevent this, Diamond uses only tough flexible stainless steel braided high-pressure fuel lines that move with the deforming structure and have a vastly superior strength and rupture resistance. They weigh and cost significantly more, but they are crticial - and therefore worth it - to prevent fuel leaks.

Fuel Tanks

Most piston aircraft carry fuel in the wings, but not all are equal in safety. Many use the wing structure, including the vulnerable leading edge as the tank itself, although even very light damage can cause a catastrophic breach. Diamond’s structural design concept was driven by a key goal: protection of the fuel tanks.

Our DA62, DA42 and DA40 have a twin wing spar design to allow the fuel to be placed in separate aluminum fuel tanks located between the massive and protective spars. Obviously, this weighs and costs more than merely filling the wing structure with fuel, but it is worth every cent in the added safety it provides.

In the DA20, the fuel cell is extremely well protected by the fuselage safety cell structure, yet separated from the cockpit, reflecting today’s modern automotive practice.

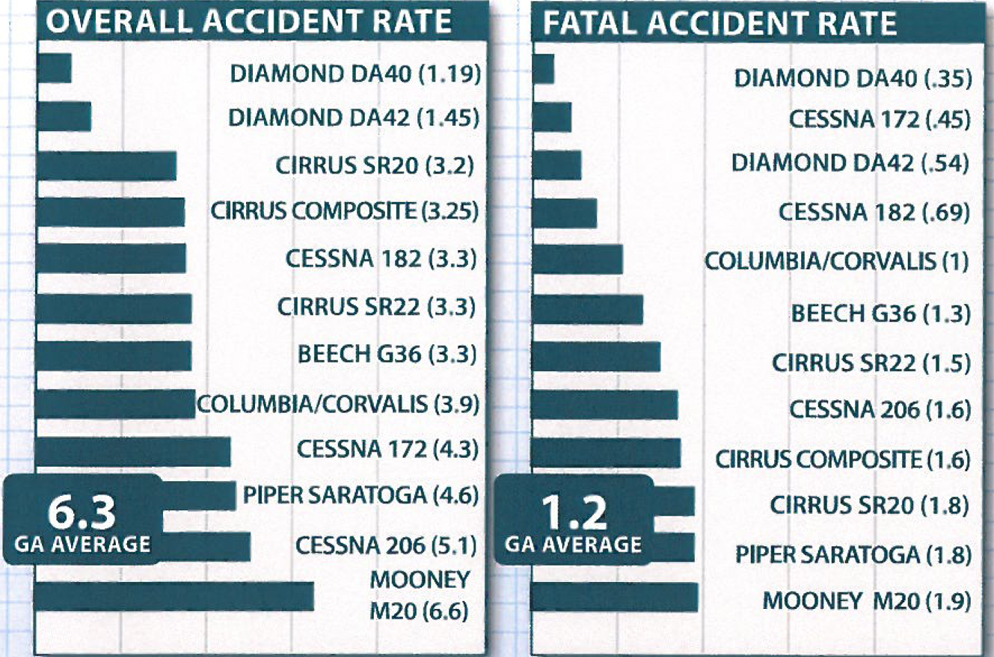

Industry-leading Safety Record

Diamond’s designs have achieved an impressive and consistent safety record over many years and millions of hours flown worldwide. Our safety record has been lauded by the aviation press and is rewarded with attractive insurance rates.

Beyond the statistics and insurance rates, safety is about minimizing the risks that are inherent to flying to better protect you and your passengers.

Shouldn’t safety be at the very top of your list when selecting your next aircraft?

(Source graphic: Aviation Consumer, January 2012)